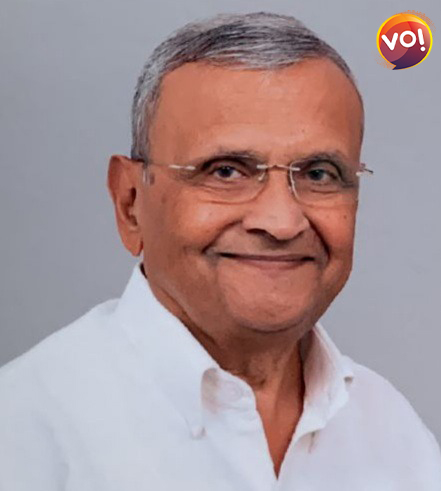

Having studied Lean management (then known as the Toyota Management System) under the Japanese guru Masaki Imai, consultant Dilip Somaiya sought to implement what he had learnt in manufacturing companies around Bangalore. This was the 80s, when he had just returned from the USA, and Japanese management was all the rage among companies all over the world. But try as he might, Somaiya did not succeed in bringing about the mindset changes required for successful implementation of Lean Management. Though he had the support of the top management, the middle managers and workers were highly resistant to what they thought was a foreign concept. That was when Somaiya hit upon the idea of bringing to bear Gandhian principles to Lean Management. “Till then I was looking for answers in American management models. But I realised the solution lay buried like a diamond in my own back yard,” he says.

Somaiya was born in Kutch and though he spent a decade studying and working in the USA and is an American citizen, he and his family have always been Gandhian (his brother is a trustee of Bombay Sarvodaya Mandal, started by Vinoba Bhave). He decided to bring Gandhian ideas like dignity of labour, elimination of waste, cleanliness is next to Godliness and leadership by example to his consulting practice. These ideas actually meshed well with Lean Management and Somaiya named the hybrid concept Gandhian Servant Leadership (GSL).

One of the early applications of GSL was at the Tanishq jewellery factory in Bangalore. The unit was then making big losses and the Tata management was considering closing it down. Tanishq’s problems were rooted in its manufacturing operations. It operated on large batch sizes, which meant it could not cater to small orders. If the showrooms needed ten necklaces of a particular design, it would make a batch of 40. This often resulted in dead inventory in the showrooms and these pieces would eventually be sent back to the factory for rework. While small family jewellers made their profits on made-to-order jewellery, Tanishq found it difficult to do so.

“The Board of Titan Industries had come around to the view that the organized sector could not compete with family jewellers in India,” recalls Jacob Kurian, who was the Chief Operating Officer of Tanishq at that time. “We were given one year to turn things around. If we did not succeed, we would be shut down. I didn’t know much about Lean management then, but I knew we had to do something completely different if we were to succeed.”

GSL is essentially a tool to break down barriers between management and workers and get them to work together in bringing about change, which people are naturally resistant to. The Tanishq managers listened to Dilip’s Gandhian ideas, but were not too enthusiastic. “We were all sceptics initially,” recalls Kurian. “But Dilip believed Gandhian principles were core to the culture change that was needed. It began with the astonishing request that we clean the staff toilets.”

It’s well known that Gandhi insisted that his Ashram inmates take turns cleaning toilets. This was meant to break the caste hierarchy and instil a sense of humility and service. Lean Management too has a system called 5S, whereby both management and workers spend time daily cleaning and organising their work spaces. Somaiya has made this a cornerstone of GSL and used it to bring a sense of equality in the organisations he has worked with. He also insists that managers move out of air-conditioned offices and relocate to the shopfloor. Ketan Chandarana, CEO of Synergy Global Sourcing in Hosur, was a 22-year-old management trainee when Somaiya first brought him under the ambit of GSL practises. “As a youngster, I remember trying to discuss things so as to be convinced. But Dilipbhai told me to just do it. I would see the results for myself later.”

One of the key concepts in Lean Management is Kaizen, where employees make suggestions for continuous improvements in operations. This is difficult if workers are not committed to their jobs, but Somaiya has demonstrated that the culture of trust that GSL seeks to promote makes it possible. Sirish Patel, CEO of WCO Consultants in Chennai, was an early convert to GSL and has been using the idea in his consulting practice, which includes companies in Rwanda and Bangladesh. When he first met Somaiya, he was the head of a factory that made leather handbags for international brands like Coach. “After implementing Lean ang GSL, we started getting 300 Kaizen suggestions a month. Everyone started participating in improving operations. It’s a great way to develop people so they rise to their full potential.”

WCO has recently implemented GSL at Tangerine Design, a Gurgaon-based company that makes leather handbags, wallets, belts and footwear for international luxury brands. “It has mellowed their culture, which used to be rather aggressive in the typical North-Indian way. After GSL, everyone is more compassionate and caring,” says Patel.